Reducing Complexity: Why Standardising Heat Exchangers Lowers Costs and Improves Reliability

In many industrial operations, heat exchangers are critical assets. They support core processes across HVAC, food and beverage, chemical processing, power generation and manufacturing. In many cases, system performance, energy efficiency and product quality depend directly on their reliability. Yet despite their importance, heat exchanger systems are often far more complex than they need to be. Over time, the accumulation of custom designs, one-off specifications and inconsistent equipment choices can quietly drive up costs and introduce unnecessary operational risk.

Standardising heat exchangers is a reliable way to reduce complexity, lower lifecycle costs and improve system reliability. Rather than limiting flexibility, standardisation creates consistency, efficiency and predictability across the entire operation. When applied effectively, it allows organisations to maintain performance requirements while reducing variation and uncertainty.

The Hidden Cost of Complexity

Custom or highly varied heat exchanger designs can seem beneficial at first, particularly when optimising for a specific requirement or site constraint. However, as systems scale, age or are modified over time, complexity often becomes a liability rather than an advantage.

Common issues include:

-

Higher engineering and design costs for each new installation

-

Longer lead times due to bespoke manufacturing

-

Increased spare parts inventory and storage requirements

-

Greater maintenance effort and higher risk of incorrect part replacement

-

Reduced operational familiarity among technicians

These challenges compound over time, particularly for organisations operating multiple sites or large arrangements of heat exchangers. What begins as a tailored solution can evolve into a fragmented asset base that is costly to manage and difficult to standardise later.

How Standardisation Reduces Capital and Operating Costs

Standardised heat exchangers use consistent designs, materials and formats across applications where possible. This approach delivers cost savings at multiple stages of the asset lifecycle, from initial procurement through to long-term maintenance and replacement.

From a capital expenditure perspective, standard units benefit from economies of scale. Manufacturing costs are lower, procurement is simpler and lead times are more predictable. Engineering teams also spend less time redesigning equipment that already performs reliably in similar conditions, freeing up resources for higher value activities.

From an operational standpoint, maintenance costs are reduced through:

-

Fewer spare parts to stock and manage

-

Faster fault diagnosis due to familiar layouts

-

Shorter downtime when replacements are readily available

-

Simplified training for maintenance personnel

Over the life of the equipment, these savings often outweigh the benefits of custom designs, particularly in environments where uptime and operational continuity are critical.

Improved Reliability Through Proven Designs

Reliability is closely linked to repetition and experience. Standardised heat exchangers are typically based on designs that have been tested across multiple installations and operating environments, allowing performance characteristics and limitations to be well understood.

This results in:

-

Fewer unexpected failures

-

Reliable performance metrics under defined conditions

-

Improved confidence in thermal and pressure ratings

-

Easier identification of wear patterns and maintenance intervals

By contrast, one-off designs may introduce unknown risks that only become apparent after extended operation, increasing the likelihood of unplanned outages or premature equipment failure.

Faster Maintenance and Reduced Downtime

When equipment is standardised, maintenance becomes faster and more predictable. Technicians are already familiar with the unit layout, gasket types, plate patterns or tube arrangements. Documentation is consistent, and procedures do not need to be relearned for every system or site.

In industries where downtime is costly, this familiarity can significantly reduce mean time to repair. In many cases, spare heat exchangers or components can be swapped immediately rather than waiting for custom parts to be manufactured, helping operations return to service more quickly.

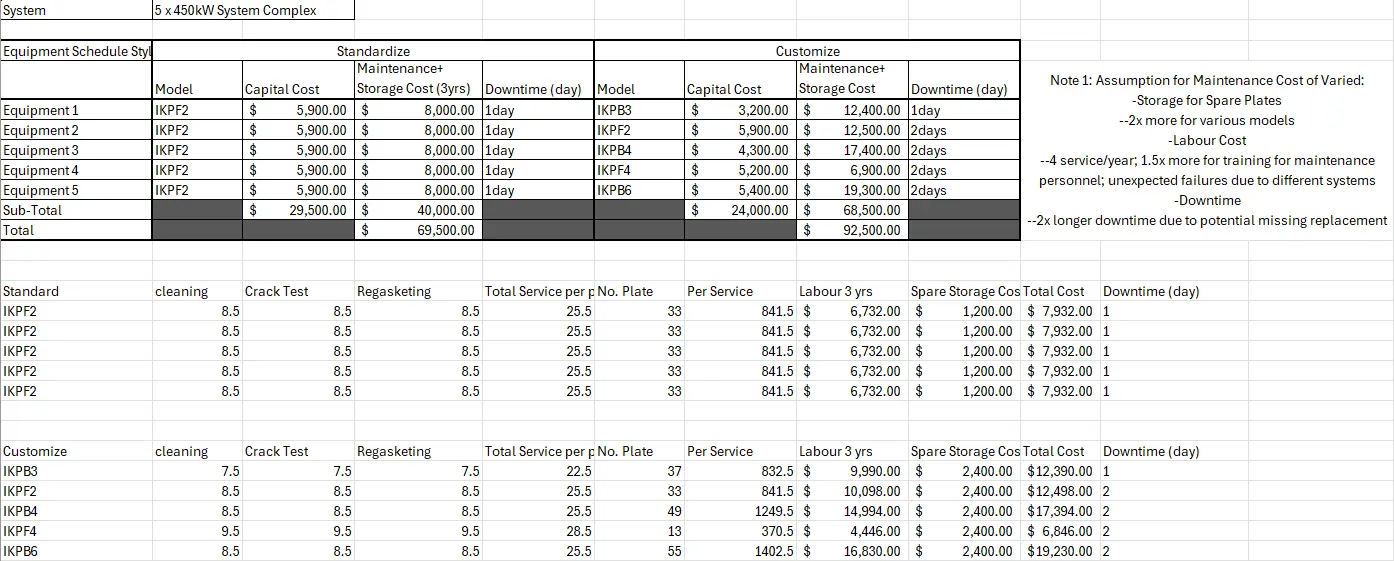

The impact of standardisation becomes clearer when comparing lifecycle utility, maintenance and downtime implications in a typical multi-unit installation. The example below illustrates the difference between a standardised five-unit 5 x 450 kW system and a customised configuration operating under similar load conditions over a three-year period.

Standard vs Customised Comparison Table

While the customised configuration shows slightly lower upfront utility costs in some cases, total maintenance and storage costs are significantly higher over three years. More importantly, downtime exposure increases due to model variation and limited parts interchangeability. The standardised configuration demonstrates lower overall lifecycle cost and reduced operational risk, primarily driven by spare part availability, training efficiency and faster service turnaround.

Supporting Scalability and Future Growth

Standardisation also supports long-term scalability. As operations expand, new systems can be integrated without reinventing specifications or retraining staff. Procurement teams can negotiate better supplier agreements, and asset management becomes more streamlined and transparent.

For organisations planning growth, mergers or multi-site operations, a standardised heat exchanger strategy creates a strong foundation for consistency, cost control and operational resilience.

When Customisation Still Makes Sense

Standardisation does not mean eliminating all custom solutions. Certain applications with extreme temperatures, aggressive media or strict space constraints may still require bespoke designs. The key is to limit customisation to where it genuinely adds value, while standardising the majority of applications wherever feasible.

A balanced approach often delivers the best outcome, combining the efficiency of standardisation with targeted customisation where it is truly justified.