Alinta Energy’s Loy Yang Power Station Case Study

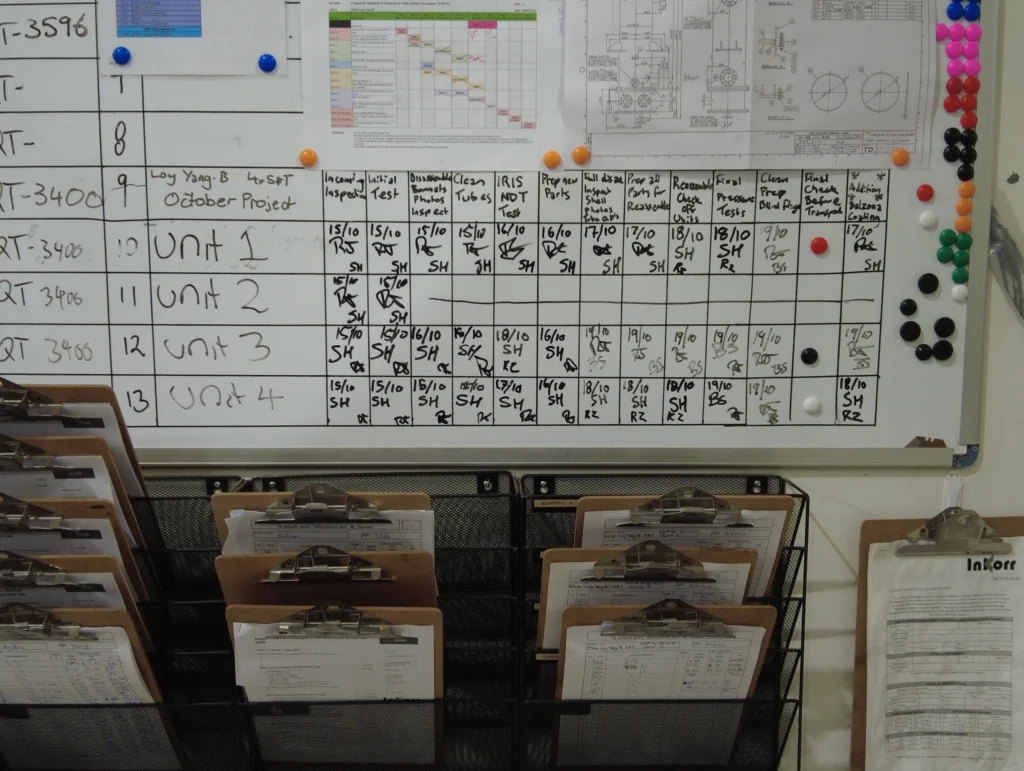

When Alinta Energy engaged InKorr to carry out a full-service heat exchanger overhaul at the Loy Yang Power Station, our team saw an opportunity to demonstrate the precision, planning, and innovation that define our work. This large-scale project involved multiple stages of disassembly, inspection, cleaning, repair, testing, and reassembly, all under tight deadlines and safety requirements.

Despite the complexity, our planning, teamwork, and in-house innovation ensured the project was completed on schedule and to the highest quality standards.

Innovative Preparation and R&D

Before work even began, we invested significant research and development time to design and fabricate custom tools that would streamline the project. This included bespoke lifting collars and a pressure washing lance purpose-built for this specific job.

These innovations proved invaluable:

-

The lifting collars made handling and rotating the large exchanger units far safer and more efficient.

-

The pressure cleaning lance simplified the tube cleaning process and worked exactly as intended.

The success of these tools not only improved workflow but also inspired future refinements to make them even more effective for upcoming projects.

Strategic Planning and Smooth Execution

From the outset, meticulous planning was central to the project’s success. Prior to mobilisation, the team ran through the full job sequence at the InKorr factory, ensuring every technician understood the process, responsibilities, and expected timeframes.

This proactive approach paid off:

-

Time estimates were accurate, with most tasks completed ahead of schedule.

-

Work staging in the factory was seamless, flowing logically through disassembly, cleaning, NDT testing, repairs, reassembly, and pressure testing.

-

Preparation allowed the team to adapt quickly, debrief effectively, and maintain momentum between stages.

As one of our technicians noted, “At all stages of the works that were in InKorr’s control, we performed so well as a team that we were consistently ahead of schedule.”

Equipment and Environmental Control

Our investment in specialised tooling and spill-control equipment ensured the project met high environmental and safety standards. Every piece of equipment performed as intended, minimising water spillage and maintaining a clean, organised workspace.

This attention to detail reinforces our reputation for both technical excellence and responsible environmental practice.

Teamwork and Safety

A standout aspect of the project was the teamwork displayed across every phase. Each technician supported their colleagues, shared knowledge, and ensured no one was left to manage a task alone.

The result was a safe, efficient work environment with zero injuries across the project’s duration. This achievement highlights our ongoing commitment to safety and collaboration as core elements of project success.

Overcoming Onsite Challenges

While the in-house stages ran smoothly, external factors at the site presented challenges beyond InKorr’s control, including weather delays and coordination with other ongoing works.

Despite these interruptions, the InKorr team remained flexible and responsive, adapting plans to recover lost time and deliver the project by the original deadline.

The experience also reinforced the importance of verifying all plans and ensuring that every aspect of onsite work is scoped in full detail before commencement. This proactive approach will help strengthen project control and minimise unforeseen delays on future multi-party projects.

Continuous Improvement and Future Focus

Every project provides opportunities to learn, and Loy Yang was no exception. The team identified a few key areas for improvement, such as establishing clearer troubleshooting protocols and reviewing the scope of subcontracted works to reduce dependency on external factors.

These reflections underline our commitment to continuous improvement, ensuring that each project builds on the lessons of the last to deliver even better outcomes for clients.

Results

By the project’s conclusion, we had:

-

Completed the heat exchanger overhaul on time and to specification.

-

Achieved zero safety incidents.

-

Demonstrated the value of in-house R&D and innovation.

-

Strengthened operational processes for future large-scale projects.

Conclusion

The Loy Yang project showcased what InKorr does best, combining technical precision, careful planning, and strong teamwork to deliver complex industrial projects efficiently and safely.

For Alinta Energy, this meant reliable, high-performance heat exchangers ready to support one of Victoria’s key power assets. For InKorr, it reinforced our reputation as a trusted partner for critical heat transfer solutions in demanding environments.